Product Machinery Cardboard Packing Board Making 80ton Kraft Paper Machine

Basic Info

| Paper Grade | High-Strength Corrugated Paper, Liner Paper |

| Basis Weight Width | 80-220g / M2 |

| Capacity | 50t/Day |

| Trimmed Width | 2650mm |

| Working Speed | 80-180 M / Min |

| Rail Gauge | 3600mm |

| Transmission Type | AC Motor Variable Frequency Speed Regulation Segme |

| Raw Material | Waste Paper, Carton Paper |

| Drive Way | A/C Converter Speed Controlling, Section Drive. |

| Main Market | Egypt, Iran, Turkey, Russia, India, Syria, Pakista |

| After Warranty Service | After Warranty Service |

| Applicable Industry | Paper Mill |

| Transport Package | 1. Fixed All The Movable Parts with Plastic Films. |

| Trademark | HY |

| Origin | China |

| HS Code | 8439200000 |

| Production Capacity | 10 Sets Per Year |

Product Description

Waste Paper Recycling Plant Paper Production Line Price Kraft Paper MachineTechnical requirement

Paper and pulp ratioPaper type: kraft paper making machinePaper weight: 80-250g/m2

Proportion of pulp: determined and adjusted by the user according tothe productOutput: 50t / 24hDesign width:Wire width (nominal): 3100mmPaper roll width: 2760mmFinished paper width: 2650mmGauge: 3600mm (subject to final design)Various speed:Designed speed: 200 m / minTransmission speed: 200 m / minRolling roller balancing speed: 500m / minWorking speed: 80-180 m / minDryness:Out of wire section: 19-21% (± 1%)After press section: 42-44% (± 1%)Before sizing: 92%Paper roll machine: 92%Arrangement of the paper machine: Stand at the roll machine andlook at the wire section, the drive is on the left (right) hand side.Paper machine layout form: Single layer layout

Raw material

kraft paper making machine Use Wheat Straw pulp, Rice Straw, Waste Books Paper, Wood Chips, Waste Paper, Bagasse, Wood pulp board, waste paper to produce Kraft paper, test liner paper, corrugated paper, fluting paper, cardboard paper.

(1) professional engineer team with 30 years experience;(2) we can supply turn-key solution without any trouble;(3) we have strict quality control system and ensure there is no unqualified product;(4) professional installation technician and clear technical training for your workers;(5) strict recalling system: if any problem of machine, we will recall it and change a new one for free;

Main Equipment

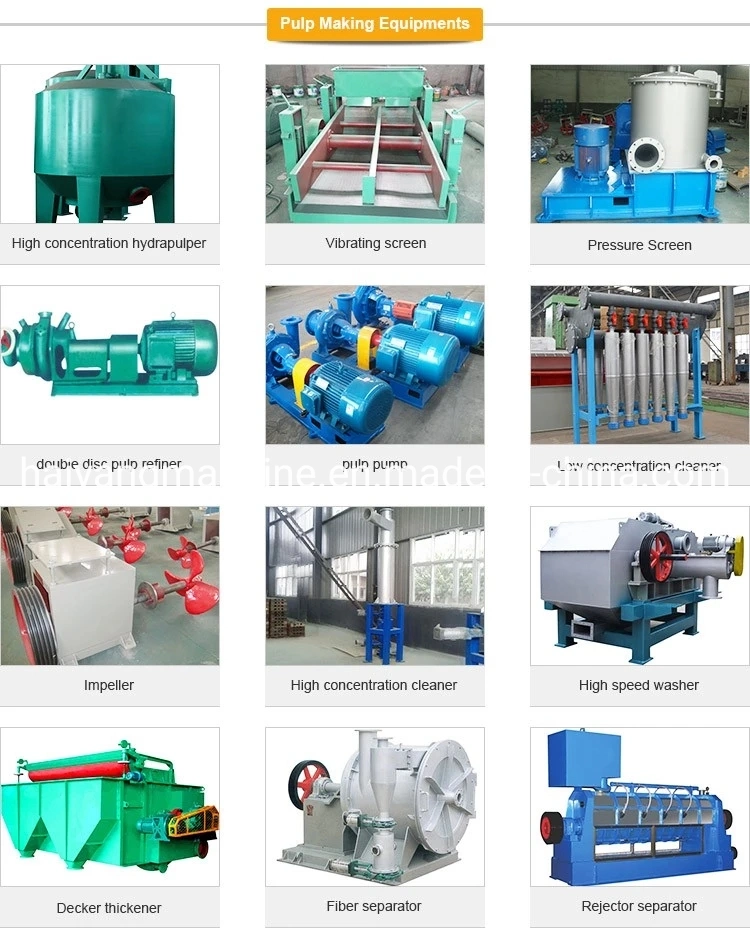

Pulp Making Equipments

kraft paper making machine use High contentration hydrapulper, Vibrating screen, Pressure Screen,Double disc pulp refiner, Pulp pump, Low concertration cleaner,Impeller, High concentration cleaner, High speed washer, Decker thickener, Fiber separator, Rejector separator

Paper Making EquipmentsHeadbox, Cylinder mold, Cylinder vat, Touch roll, Press roll, Leading roll, Dryer, Sizing machine, Calender machine, Winding machine, Rewinder, Foundation frame for kraft paper making machine

Details of kraft paper making machineDescription: Kraft and Corrugated Paper Making Machine is a production line that use waste books paper, wood pulp board, waste paper box, old corrugated carton, wheat straw pulp, wood etc. to produce Kraft paper,test liner paper, corrugated paper, fluting paper, cardboard paper.Kraft and corrugated Paper Making Machine Is Mainly Used as The Package Material, High Strength, Brown Color. Full Bleached or The Half Bleached Kraf Paper Pulp Is Light Brown Color , Cream Color, or The White Color. Most Are Jumbo Rolls, Some Are Sheets. The Kraft Paper Is Generally Made Into The Cement Paper Bags, Envolope, and Cables Protective Paper. Good Quality Waste Carton Recycle Corrugated Paper Making Machine.

Company Profile

Since 1989 Qinyang City Haiyang Papermaking Machinery has been established who is specialist in manufacturing a wide range of Paper Machines for kraft paper making machine, Test liner, Fluting paper, Corrugate, Writing & Printing, Newspaper, Duplex Board. We have more than 30 years expertise lies in applying state of the art technology to provide cost effective custom designed solutions to suit their varied requirements. The main series of the products are tissue paper machine; kraft paper/testliner /fluting paper machine;writing paper machine and special paper machine,etc. This company provides customers high efficiency and practical paper making production line with low carbon environmental protection thought. At present, our products have been sold to more than twenty provinces, cities and autonomous regions in domestic region and exported to Vietnam,Egypt, Bangladesh,Malaysia,Pakistan,Iran and other countries.

Certificate

Our service

Pre-sale Service

--24 hours phone, email, trade manager online services;

--We will supply the detailed project report, detailed general drawing, detailed flow process design, detailed layout factory drawing for you until meet your requirement;

--we welcome you to come to our paper making machine factory and paper mill factory to have a look and check;

--We will tell you all the necessary cost when set up a paper mill factory;

--We will answer you all the questions within 24 hours;

--We will send you various quality paper samples made by our paper machine for free;

--We can supply turn key-project service.

On-purchase Service

--We will accompany you to check all the equipment made by us, and help you to make the plan of installation;

--We will supply paper machine assembly drawing, the foundation and foundation load diagram, transmission diagram, formal installation drawing, use and installation instructions and a full set of technical data after signing the contract.

After-sales Service

--We will delivery the machine as soon as possible according to your requirement, within 50 days;

--We will send rich practiced experience engineers to you to install and test the machine and train your worker for free;

--We will give you one year guarantee time after the machine can run well;

--After one year, we can guide and help you to maintain the machines;

--Every 2 years, we can help to overhaul the complete machines for free;

--We will send you spare part in lower price.