High Quality Air Cushion Type Headbox for Paper Making Machine

Basic Info

| Model NO. | GLM |

| Condition | New |

| Transport Package | Wooden Case |

| Specification | Width of slurry tank nozzle is 3500mm |

| Trademark | GLM |

| Origin | Made in China |

| HS Code | 8439200000 |

| Production Capacity | 50000PCS/Year |

Product Description

Headbox for Paper Making Machine1. Type:

Air cushion double roller headbox (with computer control)

2. Technical Parameters:

- Raw Material Ratio: waste paper pulp,etc

- Finished Paper Grammage Range:fluting raw paper :90-260 g/m2.

- Tirm Width:3500mm(rolled paper width 3550mm)

- Nozzle Width:3750mm

- Working Speed:400m/min, Design Speed: 450m/min

- Concentration onto wire:fluting paper:0.8%~1.3%,

- Maximum flow of the cone inlet: m3/h.

- Paper width shrinking percentage:<=4

- Arrangement type:right side machine (looking from the reel to the headbox).

3. Material:

Stainless steel or copper is used for all parts that come into contact with the slurry and the rotating parts that need to be adjusted.

1. Feeding pipe: all stainless steel (304) (including matching flange)

2. stepped orifice plate: use a piece of plexiglass;

3. Side wall: stainless steel plate (304);

4. Upper part: stainless steel plate (304);

5. Bottom beam: with stainless steel (316L) + Q235 combination;

6. Upper lip frame: stainless steel (304);

7. The upper lip and the vertical small lip are made of stainless steel (316L);

8. Homogenizing roller: stainless seamless steel pipe (1Gr18Ni9Ti);

9. Lower lip (316L);

10. spinner: using cast aluminum;

11. Support: Q235 (outsourcing stainless steel)

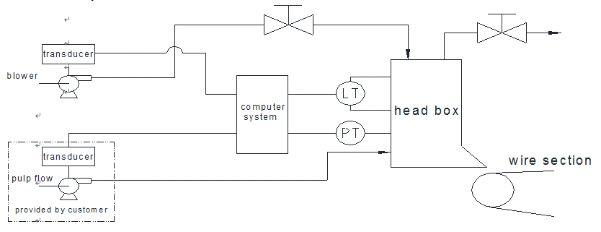

4. Control System Process as below:

Our Service:Greatland has professional technical team for installation, commissioning, and related services, also has a very wholesome file system, contacts with the user regularly.Greatland will try best to solve the problems from the customer.Within the quality guarantee, Greatland settle the problems on site.About Us:

Greatland has a professional technician team that devoted to paper-making industry and had reformed more than 100sets production line successfully. We are able to make the best proposal after completely analyzing and figuring our problems of the paper production line though paper-making progress, equipment, electric automatization and so forth. On the premise of quality assured, running speed of paper machine are made in the best condition and manufacture cost decreased on the bottom.

F&Q:Q.:Are you a factory or trading company?A.:We are a factory and manufacturer.Q.:How does your factory do regarding quality control?A.:We pay much attention on quality controlling from very beginning to the very end.Fully check and test takes before shipment.Q.:Where is your factory located?How can I visit there?A.:Our factory located at Shandong, China.You can fly to QINGDAO international airport directly.We will arrange to pick you up.Q.:What's service or guarantee can you offer?A.:One year guarantee for key parts of machine, Machine installing and worker training service, free technical support whole life.