Food Grade Pump, Lobe Pump, Lobe Pumps, Pulp Pump, Sanitary Lobe Pumps, Sanitary Pump

Basic Info

| Model NO. | AP100 |

| Type | Normal Line Gear Pump |

| Applications | Food, Chemical, Papermaking, Chemical Fiber, Pharm |

| Certification | CE, ISO |

| Seal Type | Mechanical Seal |

| I&O Direction | Horizontal/Vertical |

| Scope of Application | Transfer All Viscous Fluids |

| Transmission | Direct Connection Transmission |

| Maximum Temperature | 150degree/302f |

| Voltage | AC110V, 220-240V, 360-400V, 420-460V, 630-690V, 50 |

| Mechanisal Seal | Single Seal (Standard), Double Mechanical Seal |

| Motor | Normal Type/ABB/Siemens |

| Casing Material | Stainless Steel |

| Frenquency | 50Hz or 60Hz |

| Shaft | Stainless Steel |

| Driver | Variable Speed Motor, Geared Motor, Variable Frequ |

| Type of Connection | Quick Couple, Thread, Flange |

| Main Applications | Food Applications, Polymers, Paper Coatings, Soaps |

| Transport Package | in Export Wooden Case |

| Origin | China |

| Production Capacity | 500 Sets/ Month |

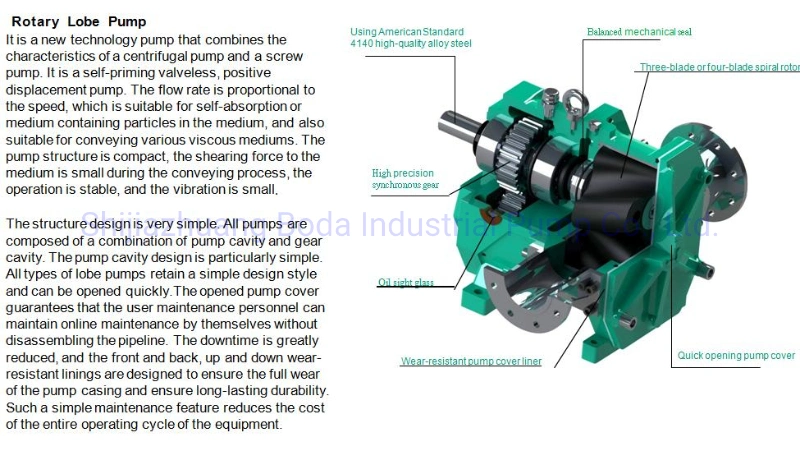

Product Description

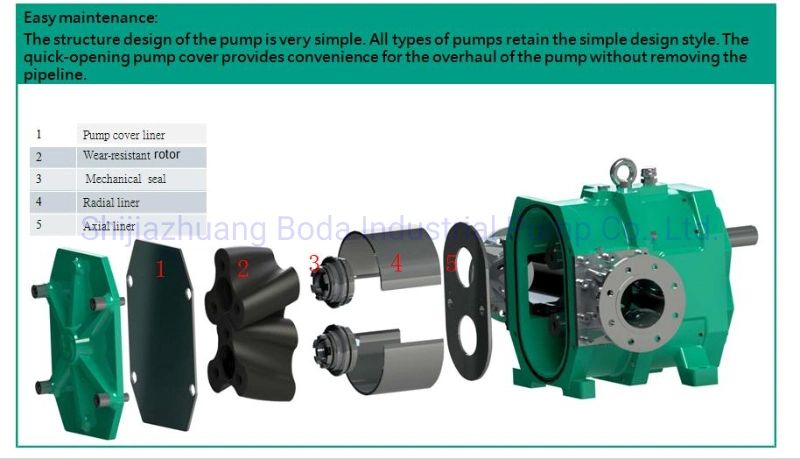

Rotor pumps are also known as colloid pumps, lobe pumps, three-lobe pumps, universal delivery pumps, etc. Higher vacuum and discharge pressure. It is suitable for the transportation of hygienic and corrosive and high-viscosity media.The mechanical energy is converted into the pressure energy of the conveying fluid through the pump, and (theoretically) has nothing to do with the discharge pressure, so that the volume becomes smaller (the length can be shortened by 100-250mm), and the performance is optimized: the overall assembly of the coupling is adopted, and the noise and wear are replaced to improve Work efficiency, get the highest efficiency.Lobe Pump/ Rotary Pump/ Rotor Pump1. Stainless Steel Food Grade Rotary Lobe Pump (Chocolate Honey Ice Cream Cosmetic)are used in a variety ofindustries including, pulp and paper, chemical, food, beverage, pharmaceutical, and biotechnology. 2. They are popular in these diverse industries because they offer superb sanitary qualities, high efficiency, reliability,corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics.3. These pumps offer a variety of lobe options including butterfly lobe, double lobe, triple lobe.4. Rotary lobe pumps are non-contacting and have large pumping chambers, allowing them to handle solids such ascherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids.

Application

Consumer chemicals rotor pump can be used for all kinds of medium, high viscosity and high solid content of material transportation. Lobe pumps are widely used in LAS, AES, AOS, MES, KI2, glycerin, sorbitol, skin cream, nutritional cream, cosmetics, toothpaste, facial cleanser, lotion, shampoo, shower gel, liquid soap, soap, detergent, washing powder paste and so on.

Rotary pumps can handle solids (e.g., cherries and olives), slurries, pastes, and a variety of liquids. If wetted, they offer self-priming performance. A gentle pumping action minimizes product degradation. They also offer continuous and intermittent reversible flows and can operate dry for brief periods of time. Flow is relatively independent of changes in process pressure, too, so output is relatively constant and continuous.

Lobe pumps are used in a variety of industries including pulp and paper, chemical, food, beverage, pharmaceutical, and biotechnology. They are popular in these diverse industries because they offer superb sanitary qualities. They have high efficiency, reliability, corrosion resistance and good clean-in-place and steam-in-place (CIP/SIP) characteristics.

Rotary pumps can handle solids (e.g., cherries and olives), slurries, pastes, and a variety of liquids. If wetted, Lobe Pumps offer self-priming performance. A gentle pumping action minimizes product degradation. They also offer continuous and intermittent reversible flows and can operate dry for brief periods of time. Flow is relatively independent of changes in process pressure, too, so output is relatively constant and continuous.

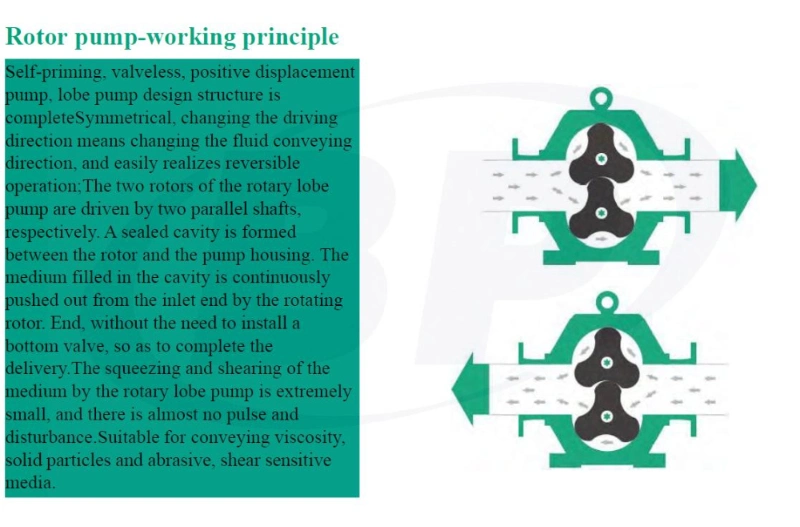

Lobe pumps are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, however, the lobes do not make contact. Lobe contact is prevented by external timing gears located in the gearbox.

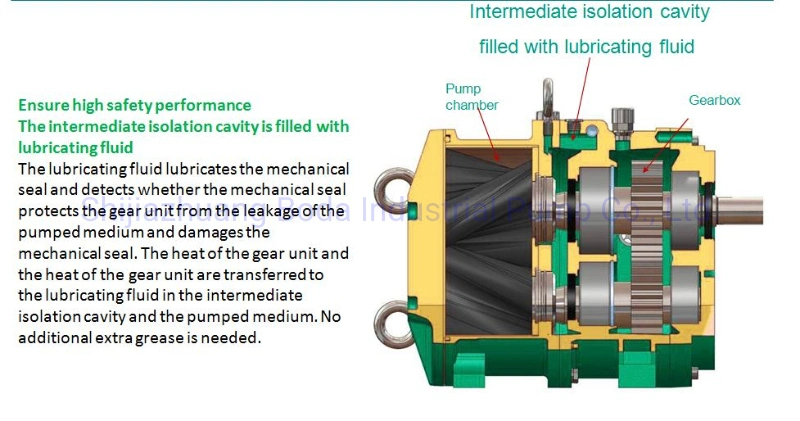

Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid, pressure is limited by bearing location and shaft deflection and this pump is noise less due to all this reason

As the Lobe Pumps lobes come out of mesh, they create an expanding volume on the inlet side of the pump. Material to be pumped (liquid, or gas, possibly containing small solid particles) flows into this cavity. Rotation of the lobes past the inlet port creates enclosed volumes of material between the rotors and the pump casing.

The material travels around the interior of the casing in these enclosed volumes between the rotor's lobes and the casing - it does not pass between the lobes.

Meshing of the Lobe Pump

Finally, the meshing of the lobes on the discharge side of the pump prevents the pumped material from returning to the inlet side. Continued pumping forces the pumped material out through the outlet port. If the discharge port is restricted - such as discharging a large volume of air into an engine's intake manifold - then pressure is created in the discharge space. A lobe pump itself does not compress the material it pumps.

Lobe pumps are frequently used in food applications because they handle solids without damaging the product. Particle size pumped can be much larger in lobe pumps than in other positive displacement types. Since the lobes do not make contact, and clearances are not as close as in other Positive displacement pumps, this design handles low viscosity liquids with diminished performance.